An industrial collaboration for thermally controlled 3D-printed metal/polymer components

02.09.2019

|

|

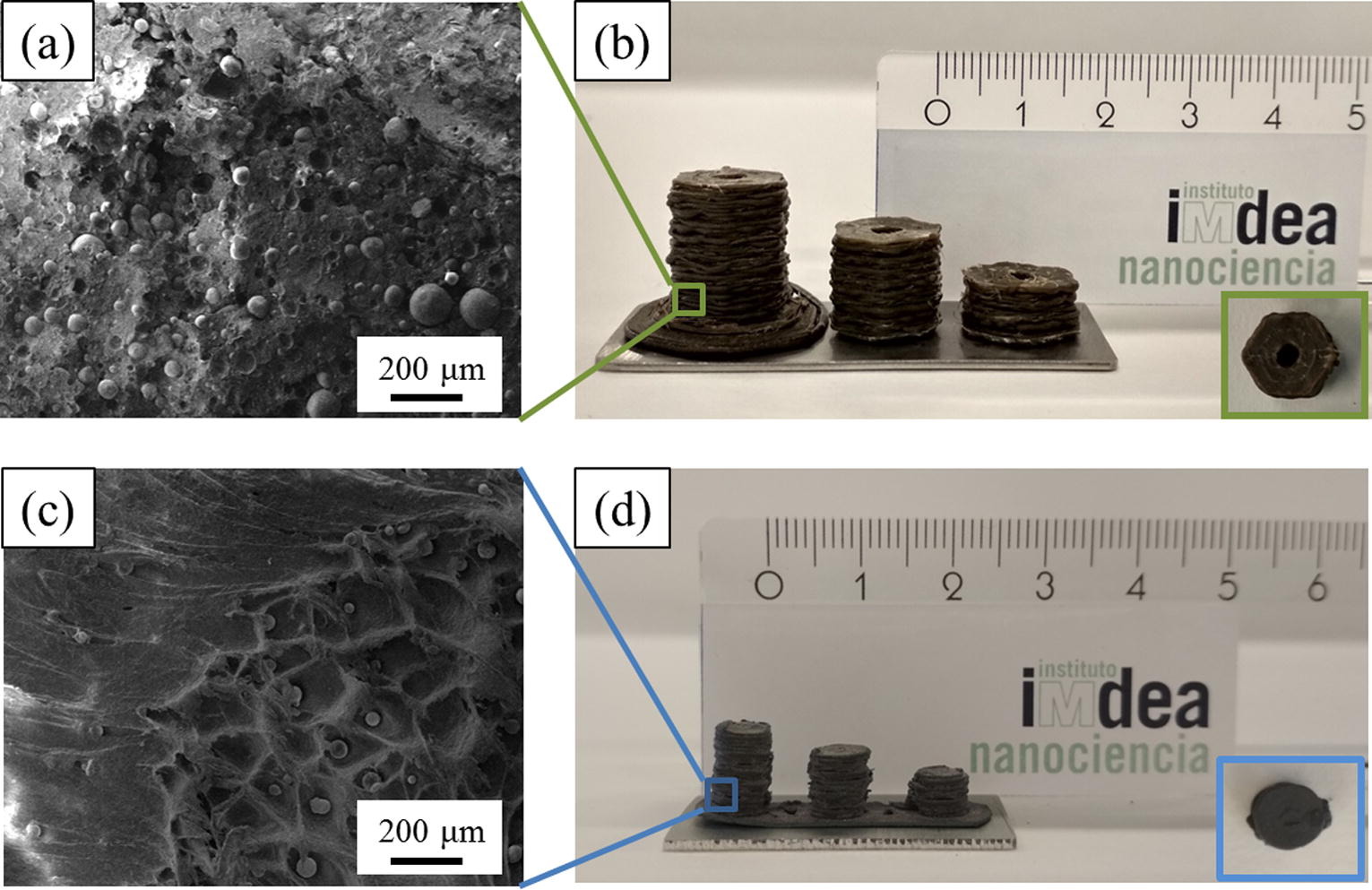

3D printed aluminum- and stainless steel-based columns. Imagen: Ester Palmero. |

IMDEA Nanociencia’s research led by Dr. Palmero jointly with the company RAMEM has resulted in successful development of thermally controlled 3D-printed proof-of-concept metallic/polymer components. This work constitutes an industrial collaboration with applicability in the aeronautic and aerospace sectors.

One of the main technological challenges when trying to combine metal particles with polymers for the fabrication of functional composites is the possibility of achieving a high metal concentration dispersed in a suitable polymer. Not every polymer is valid for the synthesis of metal-based composites since issues such as solubility are crucial. Challenges extend after the synthesis of the composite to the fabrication of a continuous wire or filament to achieve a high metal content and not just a polymeric product with dispersed metallic particles. This is of extreme importance to end with 3D-printed metal/polymer components providing high thermal conductivity (when needed) and mechanical stability in view of practical applications.

The technological novelty of the work developed by IMDEA Nanociencia and RAMEM comprises: 1) identification of polymers (acrylonitrile butadiene styrene, ABS) adequate to be combined with metallic particles (aluminum and stainless steel) for the synthesis of composites through a scalable method; 2) fabrication of continuous filaments (above 15 m long as proof-of-concept) with high flexibility and a high metal content of 80%; and 3) thermally controlled printing of components using metal/polymer filament, with no need of going to laser assisted methods. This 3D-printing method allows a personalized manufacturing and creation of complex and light geometries.

The fabrication method proposed by Dr. Palmero and coworkers eliminates manufacturing and postprocessing equipment and tooling, and minimizes material waste, saving in this way significant manufacturing cost. Moreover, this thermally controlled 3D-printing method might be combined with standard additive manufacturing technologies for the fabrication of multimaterial and multifunctional metallic components.

In view of potential technological applications in sectors such as aeronautics and aerospace, this work could open a new path (from the composite synthesis to the 3D-printing process) for the fabrication of pieces with controlled and tuned amount of metallic particles, arbitrary designs, and in consequence, tuned physical properties.

This work is the result of the collaboration between the company RAMEM S.A. and the Group of Permanent Magnets and Applications led by Dr. Bollero at IMDEA Nanociencia, and has been partially funded by the Regional Government of Madrid via the “Cheque Innovación” (Ref. 45/421504.9/17) and the project NANOMAGCOST, as well as the Centre of Excellence Severo Ochoa recognition to IMDEA Nanociencia (2017-2021).

Reference:

E. M. Palmero, D. Casaleiz, J. de Vicente, J. Hernández-Vicen, S. López-Vidal, E. Ramiro and A. Bollero. Composites based on metallic particles and tuned filling factor for 3D-printing by Fused Deposition Modeling. Compos. Part A Appl. Sci. Manuf. 124, 105497 (2019).

DOI: 10.1016/j.compositesa.2019.105497

Contact

Oficina de Comunicación Científica de IMDEA Nanociencia

This email address is being protected from spambots. You need JavaScript enabled to view it.

91 299 87 12

Twitter: @imdea_nano

Facebook: @imdeananociencia

Source: IMDEA Nanociencia